Thanks I been refining, sad fact is I'm never happy with anything that's why I have the nickname Simoan. Every time I finish one this annoying voice nags at me to make a better one. I've bought my own CNC machine now a Roland MDX40a its allot slower than 3D printing but the results are undeniably good and (once I've paid off the purchase price) good value production.

I wish I could make more I reckon I good make 3 a year but kids (either being sick or getting me sick) and modelling/production problems just drop me down to 1.5

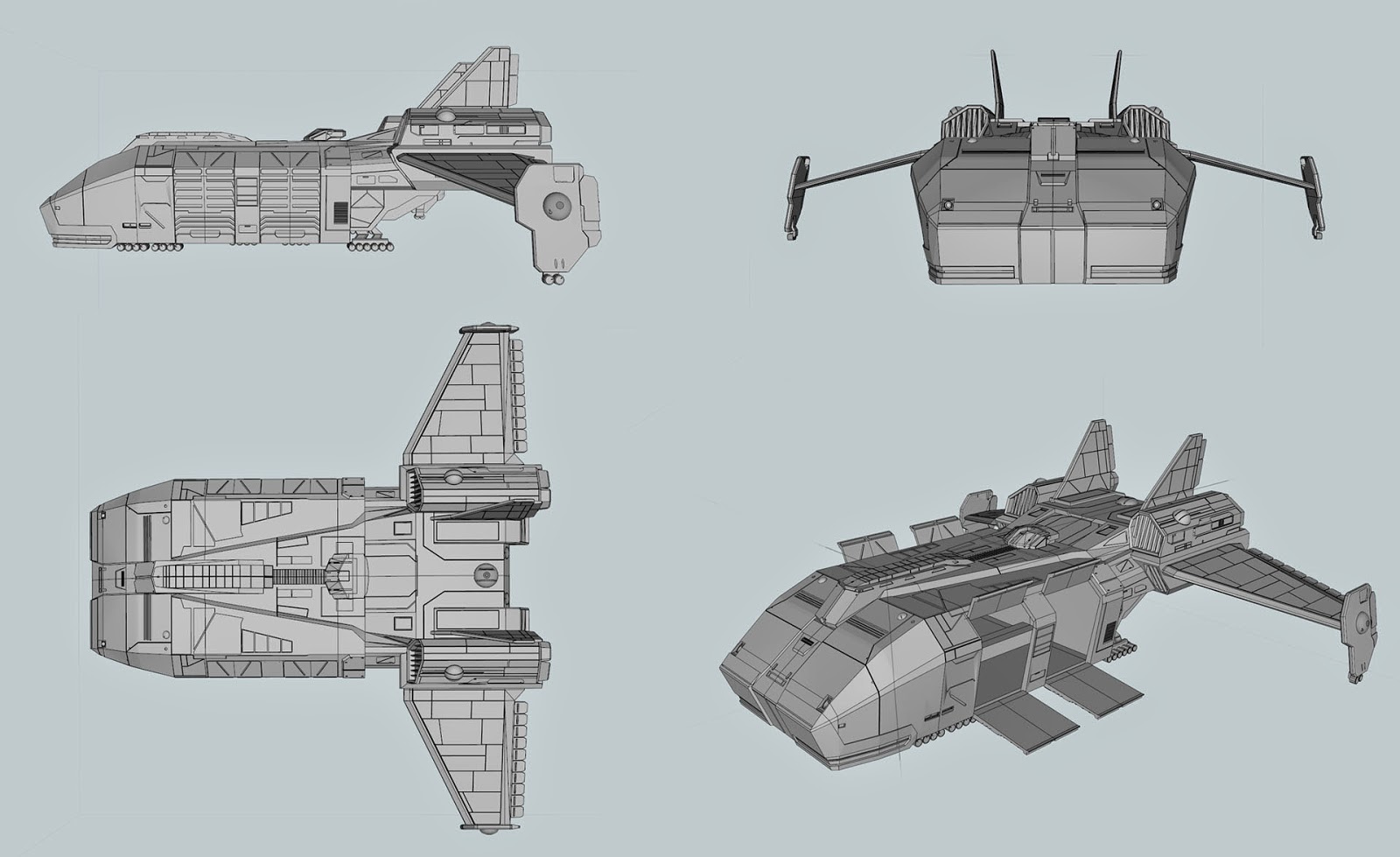

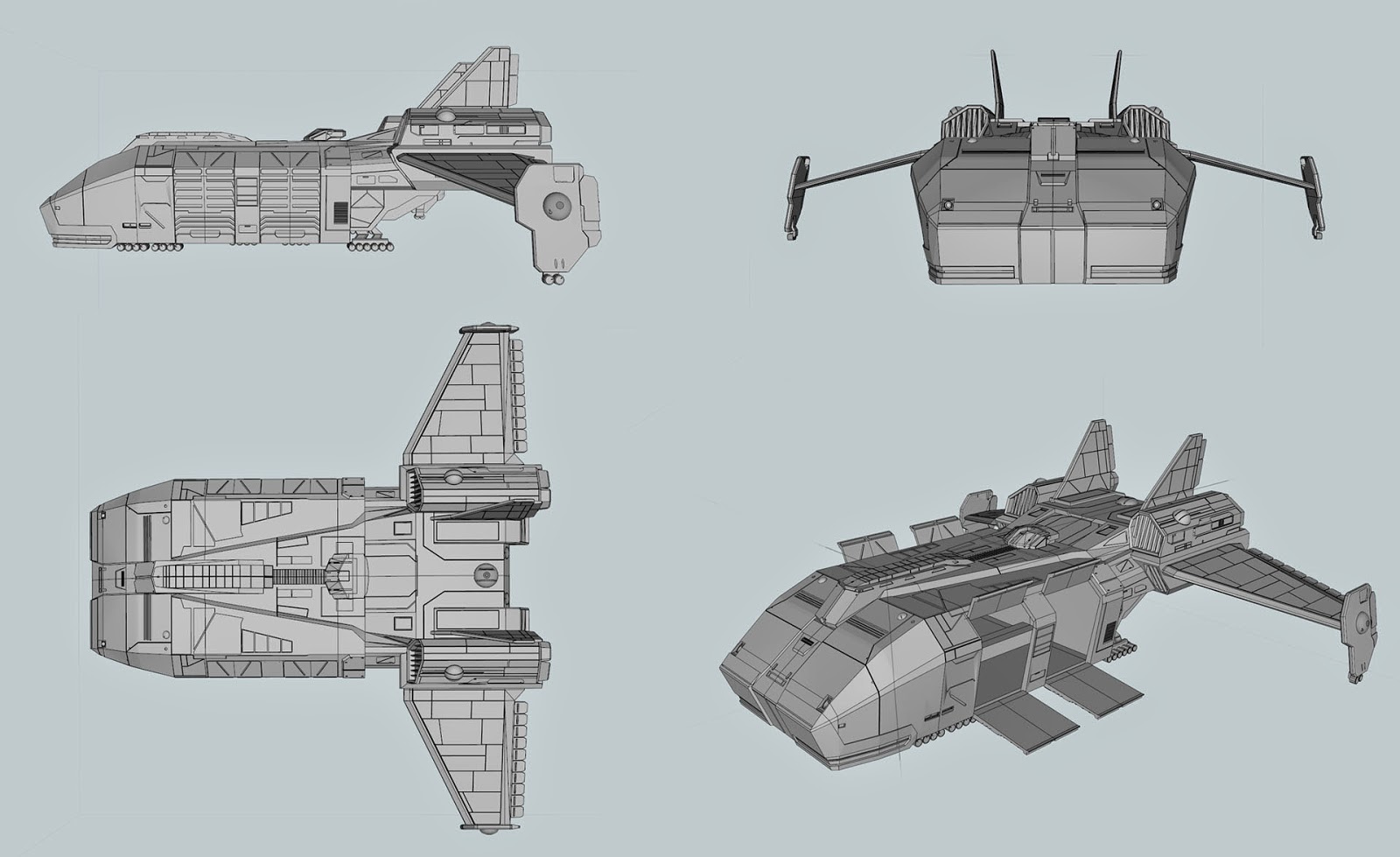

I still have to paint 4 more hunchies (2 for myself and 2 for the guys who make MWO). Then I'm going to have a bash at a leopard dropship table top scale.

I already have one SLS printed (because of the size of it) and tried to post clean it up I got pretty far (6weeks on it) but I just kept thinking there was a better way and it pushed me into the CNC route.

After the leopard something like thor/loki (together), mauler, warhammer, awesome